Fire Safety & Code Compliance for Commercial Exhaust and Dryer Vent Systems

Why These Exhaust Systems Matter

Exhaust and dryer vent systems in commercial buildings quietly move large volumes of warm, moisture-filled air every day. As these systems operate, lint, dust, and debris gradually accumulate inside the ductwork. Over time, this buildup restricts airflow and elevates internal temperatures, which eventually increases overall fire risk.

How Routine Cleaning Supports Reliable Operation

Because these systems run continuously, they require scheduled inspection to remain efficient. Additionally, as debris builds up, equipment must work harder to maintain airflow. As a result, routine cleaning becomes an effective way to maintain system stability, reduce energy use, and support safer operation.

NADCA Guidance for Commercial Facilities

NADCA emphasizes that mechanical systems must remain clean so that debris does not compromise safe operation. Therefore, for Colorado facilities with heavy laundry demand or continuous exhaust usage, routine exhaust and dryer vent cleaning plays a key role in life safety, performance, and code compliance. In addition, clean ductwork helps equipment operate more consistently throughout the year.

Information adapted from the National Air Duct Cleaners Association (NADCA), of which Ductworks, Inc. is a member.

Why Exhaust and Dryer Vent Systems Become Fire Hazards

A Problem That Develops Gradually

For many facility teams, dryer exhaust and general exhaust ductwork remain out of sight. As long as laundry cycles finish and odors leave the space, the systems are often assumed to be performing well. However, debris slowly accumulates inside the ductwork over months of operation. Consequently, airflow decreases and heat levels increase.

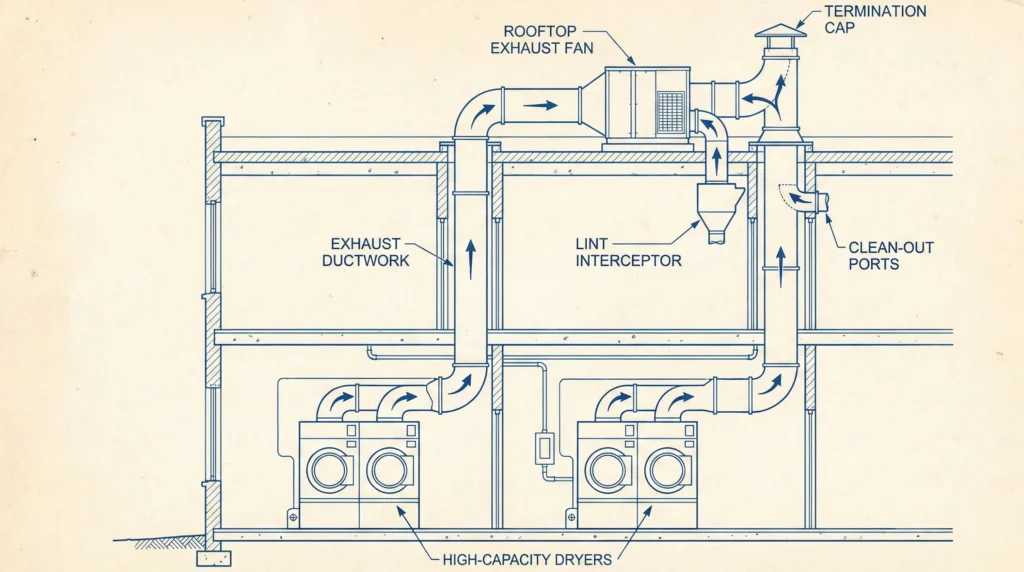

How Internal Buildup Forms

Each drying cycle sends warm, lint-filled air through long duct passages. Fine fibers cling to surfaces, especially near elbows, transitions, and terminations. Eventually, this buildup reduces the space available for air to move. As a result, dryers must run longer to complete the same workload.

Operational and Safety Impacts

- Restricted airflow: Equipment operates at higher temperatures and lower efficiency.

- Contact with heat sources: Lint rests near heating elements or burner assemblies.

- Hidden conditions: Most buildup occurs above ceilings or inside wall cavities.

When airflow gradually declines, systems experience nuisance shutdowns and unexpected maintenance issues. As a result, facility teams may notice performance problems long before they identify the underlying obstruction.

Facilities That Rely on Clean Exhaust Performance

Because laundry demand varies across industries, some facilities experience higher lint generation and therefore require more frequent cleaning. For example:

- Salons & barbershops: Towels and capes create steady lint accumulation.

- Gyms & fitness centers: Towels cycle through dryers multiple times daily.

- Hotels & resorts: High linen volume rapidly loads shared risers.

- Industrial laundries: Long duct runs intensify heat and lint concentrations.

- Hospitals & healthcare: Reliability supports patient care and infection control.

- Multi-family & senior living: Common vents serve numerous occupants.

Early Indicators Noticed by Facility Teams

- Drying cycles take longer than usual.

- Dryers short-cycle or trip high-temperature safeties.

- Humidity or warm air persists in surrounding spaces.

- Lint appears near terminations or rooftop exhausts.

- Vendors observe overheating or recurring faults.

- Exterior dryer cabinets or nearby walls feel hotter than normal during operation.

- Lint screens and filters require more frequent cleaning despite regular maintenance.

- Staff or occupants report musty or slightly “burnt” odors near laundry areas.

- Building automation or monitoring systems flag airflow or temperature irregularities.

Why Clean Dryer Exhaust Matters for Energy, Uptime, and Equipment Life

Routine dryer exhaust cleaning supports far more than fire safety. It also contributes to efficiency, productivity, and long-term equipment performance. Therefore, it becomes an essential part of an overall mechanical maintenance program.

Lower Energy Use

Clean exhaust ducts allow air to move more freely. Consequently, cycles require less time, and overall energy consumption may decrease in high-use facilities.

Improved Throughput

Faster cycle times mean laundry can be processed more efficiently. As a result, busy facilities experience smoother scheduling and higher daily output.

Equipment Longevity

When dryers operate at lower temperatures and reduced strain, mechanical components experience less wear, and equipment tends to last longer with fewer repairs.

Reduced Fire Risk

Dryer lint is naturally combustible. Routine exhaust cleaning removes this buildup and therefore decreases the likelihood of dryer-related fire events.

How Cleaning Supports Fire Code and Safety Requirements

Life-Safety Expectations

Although specific wording varies by jurisdiction, most Colorado municipalities reference national life-safety standards requiring exhaust systems to remain clear of lint and obstructions. Consequently, building owners must maintain conditions that support safe airflow and prevent combustible buildup.

Role of Local Code Officials

Fire marshals and other authorities having jurisdiction (AHJs) interpret and enforce these standards. When facilities document cleaning and maintain clear exhaust pathways, they are better prepared for inspections and ongoing life-safety reviews.

This article summarizes code-related maintenance topics. Only authorities having jurisdiction (AHJs) can interpret and enforce code.

How NADCA Principles Apply in the Field

NADCA guidelines state that HVAC and exhaust systems should be cleaned once debris interferes with airflow or safe operation. Therefore, cleaning schedules should reflect actual system conditions rather than preset dates. This condition-based approach helps align maintenance with inspection findings and day-to-day operational needs.

Cleaning Helps Meet Key Requirements

- Maintains clear airflow through exhaust pathways.

- Reduces hazards linked to lint accumulation.

- Supports equipment efficiency and stable temperatures.

- Helps prepare facilities for fire safety inspections.

- Provides documentation for insurance and compliance reviews.

Although cleaning does not replace code enforcement, it demonstrates responsible facility management. Additionally, it helps create safer operating conditions for both equipment and occupants.

How Often Should Commercial Exhaust and Dryer Vents Be Cleaned?

Condition-Based Cleaning

NADCA does not set one universal interval for all buildings. Instead, it recommends routine inspections and cleaning “as needed” when lint or debris reaches levels that restrict airflow or create hazards. Therefore, cleaning frequency should reflect the building’s actual usage patterns.

How Usage Influences Frequency

Dryer exhaust captures heavy particulate loads in relatively short timeframes. Because of this, many facilities require more frequent cleaning than standard HVAC ductwork. In high-use environments, multi-year cycles may allow buildup to accumulate gradually and unnoticed.

The table below provides general starting points based on usage and risk. However, actual intervals should always be adjusted according to inspection findings and operational feedback.

Typical Commercial Cleaning Cycles

| Facility Type | Recommended Frequency |

|---|---|

| Hotels & Hospitality | Every 6–12 months |

| Healthcare Facilities | Every 6–12 months |

| Multifamily High-Rise | Every 1–2 years |

| Gyms & Recreation Centers | Every 1–2 years |

| Industrial / High-Volume Laundry | Every 3–6 months |

Cleaning cycle examples informed by NADCA guidance and Ductworks’ work with Colorado facilities. Actual intervals depend on usage, system design, and inspection results.

*These intervals are examples, not strict requirements. Regular inspections and documented findings should determine when cleaning is necessary.

How Ductworks Cleans Commercial Exhaust and Dryer Vent Systems

System Review and Access Planning

Ductworks begins each project by reviewing the exhaust pathway. During this stage, airflow restrictions, access challenges, and system elevations are identified. Consequently, cleaning can be planned according to actual field conditions and building use.

NADCA-Standard Source-Removal Methods

After the review, mechanical agitation and negative-pressure collection methods are used to remove lint and debris. These techniques follow NADCA’s source-removal standards and help protect equipment, building finishes, and occupied areas while work is underway.

Key Steps During Cleaning

- Inspection of the entire exhaust or dryer vent pathway.

- Mechanical agitation to dislodge lint and debris from interior surfaces.

- Negative-pressure extraction to capture and remove loosened contaminants.

- Cleaning of connectors, transitions, and hard-to-reach areas.

What Facility Teams Receive

- Clear communication of findings and any areas of concern.

- Before-and-after photo documentation for safety personnel and insurance partners.

- Recommendations for future inspections and condition-based cleaning intervals.

This structured approach improves airflow, supports code-related expectations, and helps extend equipment life. Additionally, it gives facility teams confidence in the condition of their exhaust systems and the documentation they present to stakeholders.

Reduce Fire Risk with Professional Exhaust and Dryer Vent Cleaning

Ductworks helps Colorado facilities maintain safer mechanical environments through routine exhaust and dryer vent cleaning. Our NADCA-certified professionals offer field-tested experience, reliable documentation, and a cleaning approach aligned with life-safety expectations.

Request a Commercial Exhaust Cleaning Estimate