Yes, flexline ductwork can be professionally cleaned inside your home.

Homes across Colorado commonly rely on flexline ductwork. Each year, Ductworks completes hundreds of successful flexline cleanings. Our technicians follow a proven, repeatable process on every home. As a result, homeowners receive thorough cleaning with minimal disruption.

What is flexline ductwork?

How Flexline Ductwork Is Built, Installed and Maintained

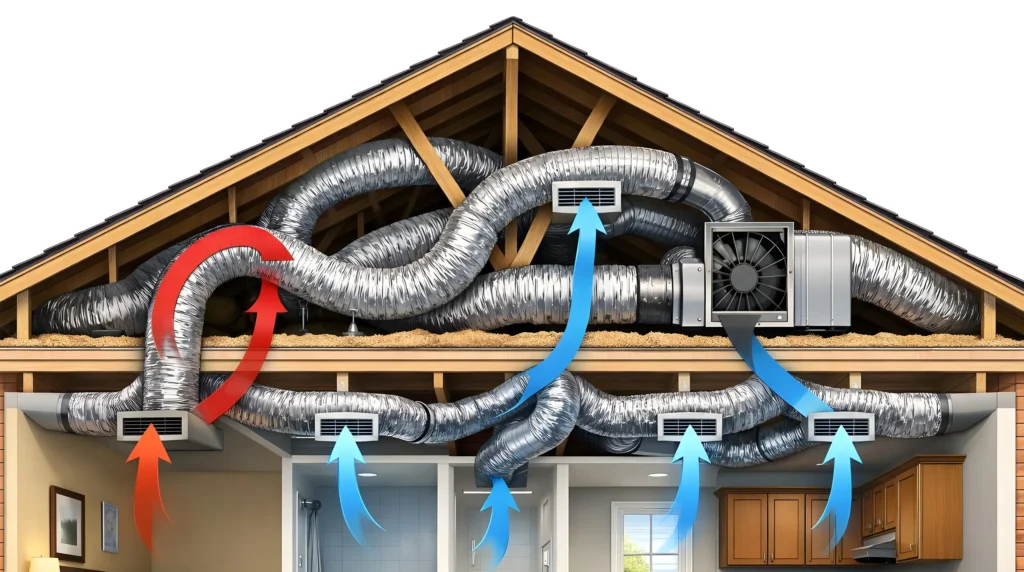

Flexline air ducts are flexible HVAC ducts built around a spiral wire helix that supports a thin plastic or foil inner liner, typically wrapped in insulation and protected by an outer jacket. This construction makes flexline ideal for routing airflow through tight or complex building spaces where rigid ductwork is impractical. Because the liner is lightweight and more delicate than sheet metal, performance depends on proper installation—well supported to prevent sagging, with minimal kinks and gentle bends to preserve airflow. For the same reason, flexline should only be serviced using controlled, flex-appropriate duct cleaning methods designed to remove buildup without tearing the liner or separating it from the wire coil.

More detail is available in a related guide.

A deeper comparison appears in The Hidden Highways of Your Home: Flex Lines vs. Sheet Metal , where duct materials and cleaning considerations are explained further.

Inspection sets the foundation for a successful flexline cleaning.

Length, connections, and material condition guide the plan.

We begin every flexline project by confirming access. If we cannot reach a section of duct, we cannot clean it properly. Our inspection covers run length, connection points, material condition, and airflow patterns. After that, we choose the method that fits your system and layout.

Before any work is performed, we inspect the system to verify access, assess material condition, and determine the appropriate cleaning method.

1) Flexline Length

Run length determines tool reach and access. Turns and transitions influence technique selection. Planning follows the actual layout of each run.

2) Connection Points

Collars and straps receive a visual check. Secure connections help maintain airflow balance. Proper handling keeps joints intact during cleaning.

3) Material Condition

We check that the metal coil feels firm and holds its shape. We also confirm the plastic liner and outer jacket look intact.

4) Duct Routing

We check for kinks or compression that can restrict airflow. We also confirm access so the duct can be cleaned effectively.

Two proven methods deliver professional flexline cleaning.

We match each method to your layout, access, and material condition.

Precision cleaning for accessible runs.

For accessible sections of flexline, the Brush & Vacuum method delivers the most thorough point-of-contact cleaning. It combines controlled agitation with immediate extraction to remove stubborn debris.

How it works:

1. The Tool

We use a power-driven rotary brush at a low-speed setting designed for delicate surfaces.

2. The Action

Soft bristles gently agitate the interior walls, loosening dust and debris without stressing the coil.

3. The Extraction

A HEPA-filtered vacuum line follows directly behind the brush head and captures particles the instant they break free.

Why choose this method?

This technique delivers concise point-of-contact cleaning. Because the brush touches the surface, it creates a uniform result when the duct layout allows access.

- Most Thorough Technique Physical contact removes stubborn dust layers.

- Low-Speed Safety Controlled rotation helps prevent liner tears caused by high-speed tools.

- Immediate Capture HEPA suction at the source minimizes dust migration.

The Limitation: Reach Run length and routing limit this method. Long or complex runs may perform better with the Air Whip method.

How the Air Whip cleans without damage.

The Air Whip (often called air washing) uses compressed air to loosen debris instead of scraping the liner. Technicians often choose it for flexible ductwork because it reduces stress on the inner liner while still delivering strong results.

How it works:

1. The Tool

We connect a flexible hose to a high-pressure compressor and use a nozzle with soft rubber whips.

2. The Action

Compressed air drives the whips into motion, agitating dust without heavy impact on the liner.

3. The Wash

The whipping action lifts debris into the negative airstream, where a HEPA-filtered vacuum captures it immediately and safely contains it.

Why is this ideal for flexline?

Standard rotary brushes can catch on the wire helix or tear the liner. Air whips avoid that risk by cleaning with airflow and soft contact.

- Non-Abrasive Contact Rubber whips loosen dust without puncturing the liner.

- Navigates Bends The flexible hose moves through turns and transitions more easily than rigid tools.

- Protects the Wire Helix The whips clean around ribs without snagging or pulling.

- Airflow Driven High-velocity air moves heavier debris while keeping contact light.

- Protects Internal Structure Gentle action helps preserve the liner-to-coil connection.

- Maintains Insulation Shape Controlled handling helps prevent insulation compression around the duct.

Request a flexline duct cleaning estimate.

Experience, Training & Specialized Equipment

Ductworks brings the experience, specialized training, and professional-grade equipment required to clean flexible ductwork safely and effectively. Our team understands the limits of flexline systems and uses methods designed to protect the liner, preserve airflow, and deliver reliable results. If you have questions about your ductwork or would like to learn whether flexline cleaning is right for your home, call us or submit a convenient Residential Estimate Request—we’re here to help.