Understanding Ticking Noises Coming From Your Air Ducts

Ticking sounds in air ducts can be distracting and concerning. The noise is often heard when the system starts or stops. It may also echo through several rooms, which makes it feel louder than it really is. Because of this, many homeowners begin to wonder if something is wrong with the HVAC system.

Ticking in air ducts is usually caused by metal expanding and contracting as air temperature changes. This is called thermal expansion. However, ticking can also be linked to loose duct connections, undersized ductwork, dampers, or other mechanical issues. Debris is not typically the cause, but it can be a factor in some homes.

How Thermal Expansion Creates Ticking Sounds

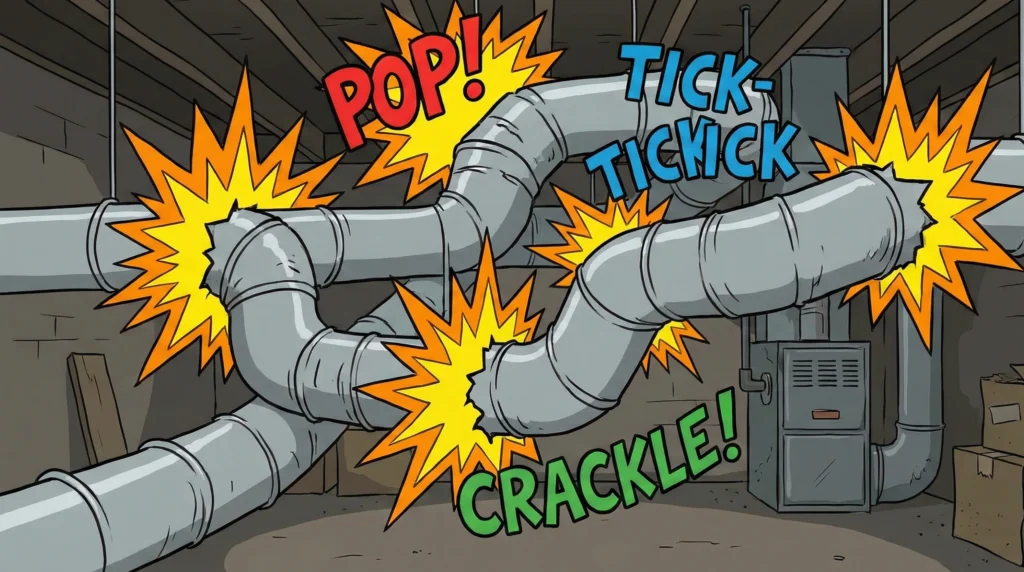

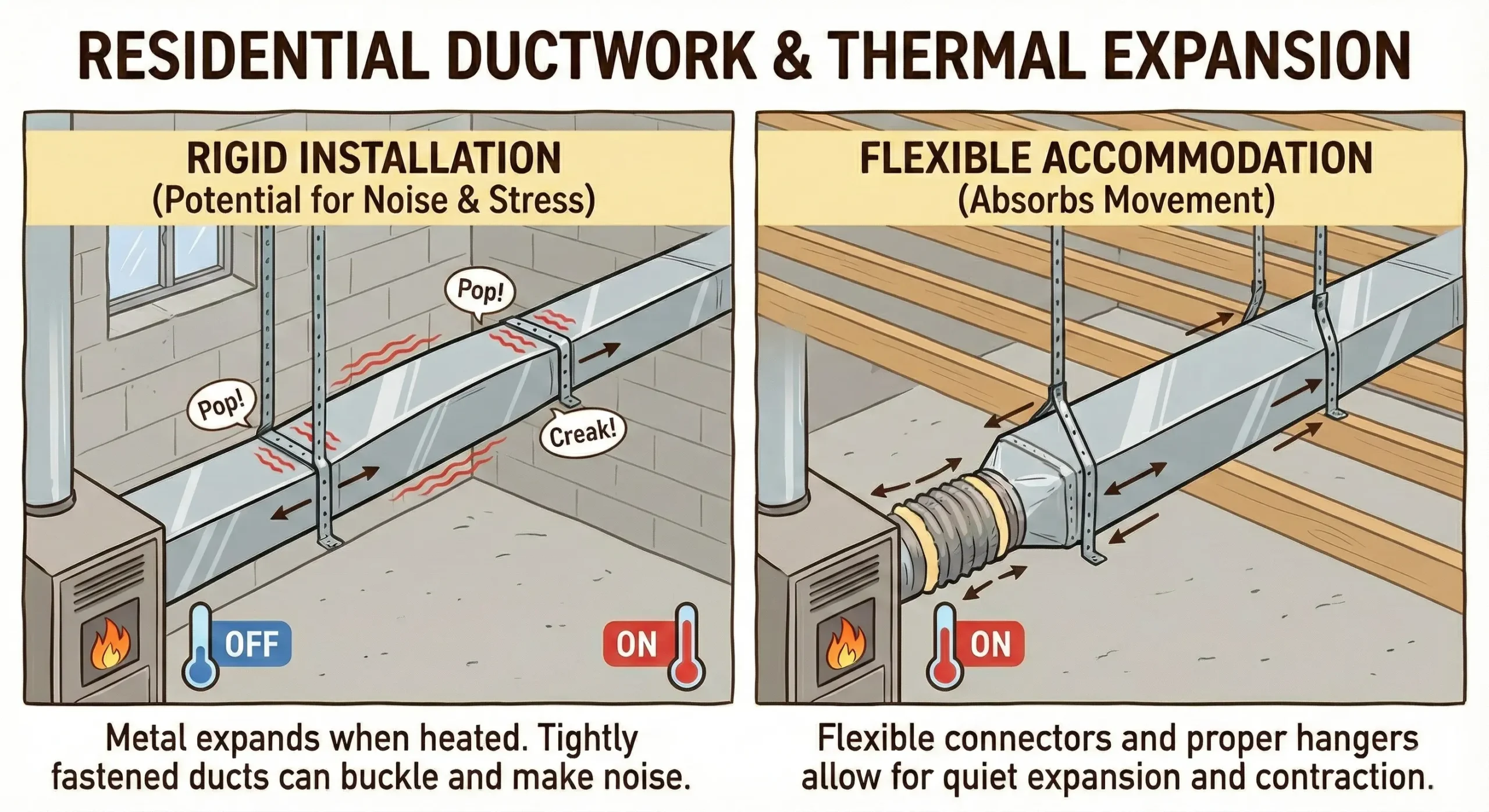

Metal ductwork expands as warm air passes through the system. It then contracts as the ducts cool down. As these small movements occur, the metal may shift against framing, hangers, or other pieces of duct. Because of that movement, light ticking, popping, or pinging sounds are often heard.

This behavior is especially common in older homes. Rigid framing, older fasteners, and long metal trunk lines can all increase noise. The sounds are often brief and are usually heard only at the start or end of a heating or cooling cycle. In many homes, this type of ticking is considered normal system operation.

Other Reasons Ducts May Tick, Tap, or Rattle

Loose Duct Connections and Hardware

Joints, hangers, or screws can loosen over time. When the blower turns on, vibration is created in the ductwork. That vibration can cause metal parts to tap against framing or other ducts. As cycles continue, the ticking may grow more frequent or more noticeable.

Undersized or Poorly Supported Ductwork

If ducts are undersized for the air volume, pressure changes become more extreme. Panels may flex as the blower starts and stops, which produces sharp ticking sounds. When supports are missing or spaced too far apart, ducts can move and make contact with nearby framing members.

Vent Registers and Dampers

Supply registers and dampers can shift when air begins to flow. Loose grilles may rattle against drywall. Manual dampers inside the duct can also move slightly, which can create repetitive tapping during each cycle. These parts often need minor adjustment or tightening.

Debris and Foreign Objects in the Ducts

Debris is not usually the main cause of ticking. However, it can be involved in some homes. Small pieces of construction material, fallen screws, or other foreign objects may move when airflow starts. As these items shift inside the duct, light tapping or ticking sounds can occur near certain vents.

Why Basement Trunk Lines Sometimes Pop Loudly

The main trunk lines in a forced-air system are the primary air distribution ducts attached to the furnace. These large steel ducts often include shallow bends or creases in the metal called crossbreaks. They are formed in the steel to provide structural integrity and help keep the duct panels stiff.

Over many years of operation, air is either drawn through these ducts or pushed through them. As this happens, the repeated pressure changes can slowly weaken the metal panels. When the blower starts or stops, the duct surface can flex and then snap back into place. That movement creates a distinct popping sound that often seems to come from the main trunk line.

In some cases, the popping can be reduced by gently pushing into the steel panel to change the way it flexes. In other situations, a reinforcement bracket or stiffener may be added by an HVAC professional. This support helps the metal hold its shape and can lessen the popping during normal system operation.

When Ticking Is Normal and When It May Signal Trouble

Examples of Normal Ticking

Mild ticking that appears briefly at the start or end of a cycle is often normal. The sound usually fades quickly as temperatures stabilize inside the ducts. Homes with long metal runs or older ductwork experience this behavior more often.

If comfort is good and airflow feels consistent, the system is often operating as expected. In these cases, homeowners may simply choose to monitor the noise over time.

Signs the Noise Needs Attention

Ticking that grows louder or continues throughout the entire cycle can indicate a problem. In addition, noises that begin suddenly after repairs, remodeling, or equipment replacement should be noted. These changes may suggest loose ductwork, shifting supports, or airflow issues.

When noises are combined with comfort problems, a professional review is recommended. The system may be working harder than it should to move air through the ductwork.

Things Homeowners Can Observe When Ticking Appears

- Notice when the ticking starts and stops during each cycle.

- Compare different rooms to see if the noise is louder in one area.

- Lightly touch a vent grille to see if the sound changes or softens.

- Look for visible gaps, sagging ducts, or loose connections in accessible areas.

- Pay attention to any new drafts or hot and cold spots in the home.

- Note if the ticking began after new equipment or renovation work.

- Listen for rattling from dampers or registers when they are adjusted.

- Watch for dust puffs or unusual odors when the system first starts.

How Ductworks, Inc. Addresses Ticking, Popping, and Other Duct Noises

In many homes, mechanical or airflow issues are first evaluated and corrected by an HVAC contractor. They may adjust equipment, modify ductwork, or add supports to address the source of the ticking or popping noise.

Once that work is complete, Ductworks, Inc. often becomes the final step in the process. Our role is to clean the interior of the duct system and remove debris, dust, and other foreign material so the air ducts are left clean and the system can operate more quietly.